Acetylene plant

-

Brief Introduction of dissolved acetylene filling process introduction

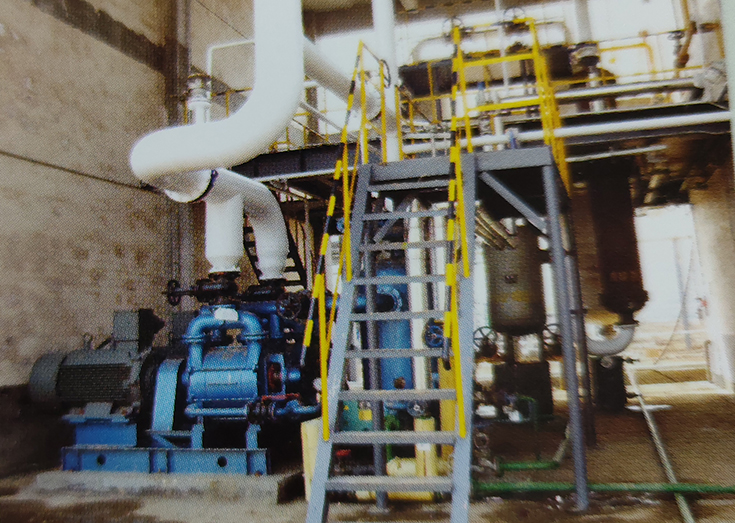

After being broken in calcium carbide storehouse, the calcium will be sent into calcium carbide feeding bucket (V101). and moved to the intermediate calcium carbide warehouse . when feeding,electric hoist(L101) can be used to hoist the bucket onto the generator hopper, calcium carbide bucket will feed the calcium carbide into hopper after nitrogen replacement, and then the calcium carbide will be automatically thrown into acetylene generator (T101) by magnetic oscillator to generate acetylene after reaction with water. Apart of the acetylene from the generator will be led into gas holder( V103). and the other part will pass through&washing column and then flow into purifier (T102). After purification, the acetylene will be sepatated by passing though low-pressure water separators(S101)and pressurized by acetylene compressor(C101). The pressurized acetylene will flow into fully automatic mole-sieve high=pressure automatic dryer(G101) to remove moisture content, and then it is sent to the filling station(M102) for bottle filling. Calcium carbide slag water discharged from the generator will return to generator to be used after clarification, calcium carbide slag can be taken away for waste acid treatment, brick marking ,roof foundation making ,etc.

Main specifications and technical data of complete sets of dissolved acetylene equipment

Process flow diagram of complete sets of dissolved acetylene equipment

Brief Introduction of acetylene pipeline conveying process

After being broken in calcium carbide storehouse, the calcium will be sent into calcium carbide feeding bucket (V101). and moved to the intermediate calcium carbide warehouse . when feeding,electric hoist(L101) can be used to hoist the bucket onto the generator hopper, calcium carbide bucket will feed the calcium carbide into hopper after nitrogen replacement, and then the calcium carbide will be automatically thrown into acetylene generator (T101) by the intertial to generate acetylene after reaction with water. Apart of the acetylene from the generator will be led into gas holder( V103). and the other part will pass through the cooling & washing column and then flow into cleaning column (T103)and neutralizing column (T105). After purification, the acetylene will be pressurized by acetylene compressor(C101)and removed moisture content by dryer(A101) and then it is sent into pipe network for the next process. Calcium carbide slag water discharged from the generator will return to generator to be used after clarification, calcium carbide slag can be taken away for waste acid treatment, brick marking ,roof foundation making ,etc.

Specifications and technical data of complete sets of pipeline-transport-acetylene equipment

Process flow diagram of complete sets of pipeline-transport -acetylene equipments